Chapter 10

Interference Fit According to DIN 7190

10.1 General Information

The interference fit is a frictional shaft-hub-connection. The joint pressure in the friction surfaces  that is

necessary for the power transmission, is generated by the deformation of shaft and hub. According to the

manufacturing method, you have to distinguish between a shrink and force fit. Shrink-fitting is a procedure in

which heat is used to produce a very strong joint between two pieces of metal, one of which is

inserted into the other. Heating causes one piece of metal to contract or expand on to the other,

producing interference and pressure which holds the two pieces together. In a force fit of cylindrical

parts, the inner member has a greater diameter than the hole of the outer member. The calculation

takes place according to DIN 7190 for cylindrical interference fits. In addition, the influence of the

centrifugal force, the stepped hub geometry, torque, radial force and bending moment are considered as

well.

that is

necessary for the power transmission, is generated by the deformation of shaft and hub. According to the

manufacturing method, you have to distinguish between a shrink and force fit. Shrink-fitting is a procedure in

which heat is used to produce a very strong joint between two pieces of metal, one of which is

inserted into the other. Heating causes one piece of metal to contract or expand on to the other,

producing interference and pressure which holds the two pieces together. In a force fit of cylindrical

parts, the inner member has a greater diameter than the hole of the outer member. The calculation

takes place according to DIN 7190 for cylindrical interference fits. In addition, the influence of the

centrifugal force, the stepped hub geometry, torque, radial force and bending moment are considered as

well.

10.2 Application

DIN 7190 defines the calculating basis for interference fits with cylindrical surfaces whose parts are made of

metallic materials. This standard applies mainly for the common mechanical engineering but can be used also in

other fields (e.g., precision engineering). The calculation method DIN 7190 applies for interference fits

with a constant axial length of inner and outer part (see figure 1). The calculation can be used

approximately for interference fits according to figure 2. Stress increases in the area of the hub edge are not

considered.

10.3 Selection of Fit/Tolerances

For a comfortable selection and calculation of suitable tolerances, a dialog window for the selection of fits is

included. This dialog window contains the tolerance system according to DIN ISO 286 including all IT

classes.

In DIN ISO 286, the tolerances for the diameter are defined up to 500 mm. The desired tolerance field can be

selected for hub and shaft from a listbox. An individual input of the upper and lower deviation is also

possible. The lowest and highest interference as well as the fit type for the nominal diameter will be

displayed. For the calculation of possible fits, the IT scope can be selected. The following IT scopes are

available:

- User-defined (the IT scope can be defined individually)

- Gauge (IT classes 1 to 5)

- Common mechanical engineering (IT classes 6 to 11)

- Rolled, pressed and forged products (IT classes 12 to 16)

- All (IT classes 1 to 18)

In order to find the required fit, different options are available. Based on the specified loads, the minimum

interference and the maximum interference are determined. These values will be displayed automatically in the

field ‘Calculation of possible fits’ and provide the basis for the dimensioning and selection of appropriate

tolerances. In addition, there is the possibility to define a tolerance field for the hub and shaft. Select the option

‘Show only preferred fits’ and click the button ‘Search fits’ and all possible fits will be displayed. Then just choose

the right fit.

10.3.1 Selection of Fit

Click the button ‘Selection’ in order to open the fit calculator and to let the calculation module propose a

suitable fit. The fit calculator provides the tolerance system according to DIN ISO 286 including all IT

classes. The upper part of the fit calculator allows to choose the tolerance field for the hub and the

shaft.

For the selected tolerance the upper deviation and the lower deviation for shaft and hub will be displayed.

Furthermore, the fit type as well as the highest and lowest interference will be specified.

The deviations of shaft and hub can be entered manually. In order to do so, please enable the option ‘Activate

the input of user defined tolerances’.

10.3.2 Calculation of Fit

You can specify the lowest and highest interference. If you have defined all data in the main mask before, the

required lowest and highest interference will be entered automatically.

Clicking the button ‘Search fits’ shows all possible fits. The message ‘More than 500 fits were found. Only

preferred fits are shown’ may occur. Please confirm this message with ‘OK’ and choose a fit from the

listbox.

The option ‘Show only preferred fits’ is activated automatically and all preferred fits will be displayed in the

listbox.

Please note: The option ‘Show only preferred fits’ is enabled by default. The list of fits is limited. Disable this

option and click the button ‘Search fits’. The number of fits increases.

10.4 Automatic Dimensioning Functions (Calculator Button)

The button for the dimensioning functions is marked by a calculator symbol and is located next to the input

fields. If you click on the dimensioning buttons, you get a suggestion for an appropriate input value.

The calculation of the value is carried out so that the given minimum safety is fulfilled. The default

value for the minimum safety is set to ‘1.2’. Clicking the button ‘Options’ allows you to change this

value. A dimensioning function is available for the joint diameter, the length, the torque and the axial

force.

10.5 Influence of Centrifugal Force

The influence of the centrifugal force on the interference fit by the input of a speed is considered according to F.

G. Kollmanns, Braunschweig ‘Rotierende Pressverbände bei rein elastischer Beanspruchung’ (Konstruktion 33,

1981 H.6, pp. 233-239).

10.6 Additional External Loads

In addition to the consideration of axial and tangential forces, a radial and a bending moment can be specified.

The calculation is carried out according to Mr. Prof. Gropp ‘Das Übertragungsverhalten dynamisch

belasteter Pressverbindungen ...’ and Mr. Prof. Hartmann ‘Berechnung und Auslegung elastischer

Pressverbindungen’.

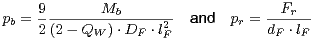

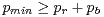

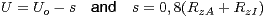

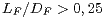

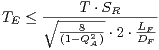

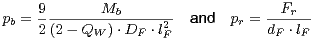

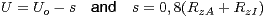

Resulting from the given loads for the bending moment and radial force, the additional external loads may be

determined from the following equations:

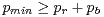

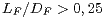

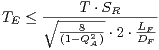

For a too small minimum joint compression, the hub lifts off and a so-called gaping joint occurs. A gaping joint

minimizes the joining surface available for the power transmission and is imperative to avoid. To avoid a gaping

joint, the following condition has to be fulfilled:

If this condition is not fulfilled, then an appropriate warning/message appears.

10.7 Operating Factor (Application Factor)

The operating factor (application factor) is determined according to DIN 3990. The following table gives some

values.

|

|

|

|

|

Application Factors  According to DIN 3990-1: 1987-12 According to DIN 3990-1: 1987-12

|

|

|

|

|

|

| Working Characteristics | Working Characteristics of the Driven Machine

|

|

|

|

|

|

| of the Driving Machine | Uniform | Light Shocks | Moderate Shocks | Heavy Shocks |

|

|

|

|

|

| Uniform | 1,0 | 1,25 | 1,5 | 1,75 |

|

|

|

|

|

| Light Shocks | 1,1 | 1,35 | 1,6 | 1,85 |

|

|

|

|

|

| Moderate Shocks | 1,25 | 1,5 | 1,75 | 2,0 |

|

|

|

|

|

| Heavy Shocks | 1,5 | 1,75 | 2,0 | 2,25 or higher |

|

|

|

|

|

| |

10.7.1 Working Characteristics of the Driving Machine

Uniform: e.g., electric motor, steam or gas turbine (small, rarely occurring starting torques)

Light Shocks: e.g., electric motor, steam or gas turbine (large, frequently occurring starting torques)

Moderate Shocks: e.g., multiple cylinder internal combustion engines

Heavy Shocks: e.g., single cylinder internal combustion engines

10.7.2 Working Characteristics of the Driven Machines

Uniform: Steady load current generator, uniformly loaded conveyor belt or platform conveyor, worm conveyor,

light lifts, packing machinery, feed drives for machine tools, ventilators, light-weight centrifuges, centrifugal

pumps, agitators and mixers for light liquids or uniform density materials, shears, presses, stamping machines,

vertical gear, running gear

Light Shocks: Non-uniformly (i.e. with piece or batched components) loaded conveyor belts or platform

conveyors, machine-tool main drives, heavy lifts, crane slewing gear, industrial and mine ventilators, heavy

centrifuges, centrifugal pumps, agitators and mixers for viscous liquids or substances of non-uniform density,

multi-cylinder piston pumps, distribution pumps, extruders (general), calendars, rotating kilns, rolling mill stands,

continuous zinc and aluminium strip mills, wire and bar mills

Moderate Shocks: Rubber extruders, continuously operating mixers for rubber and plastics, ball mills (light),

wood-working machines (gang saws, lathes), billet rolling mills, lifting gear, single cylinder piston

pumps

Heavy Shocks: Excavators (bucket wheel drives), bucket chain drives, sieve drives, power shovels, ball mills

(heavy), rubber kneaders, crushers (stone, ore), foundry machines, heavy distribution pumps, rotary

drills, brick presses, de-barking mills, peeling machines, cold strip c, e, briquette presses, breaker

mills

10.8 Coefficients of Friction

The following table provides some approximate values for the coefficients of adhesion/coefficients of friction for

shrink fits according to DIN 7190. The values are on the safe side and can be used for sliding in circumferential

and longitudinal direction.

|

|

| Coefficients of Adhesion for Shrink Fits in

|

| Longitudinal and Circumferential Direction During Sliding

|

|

|

| Mating of Material, Lubrication, Joining | Coefficients of

Adhesion

|

|

|

| Steel/Steel pair | |

|

|

| Pressurized oil assembly normally joined with mineral oil | 0,12 |

| Pressurized oil assembly with degreased surfaces joined with glycerine | 0,18 |

Shrink fit normally after heating the outer part up to  C in an electric kiln C in an electric kiln | 0,14 |

Shrink fit with degreased surfaces after heating up to  C in an electric kiln C in an electric kiln | 0.20 |

|

|

| Steel/Cast iron pair | |

|

|

| Pressurized oil assembly normally joined with mineral oil | 0,10 |

| Pressurized oil assembly with degreased surfaces | 0,16 |

|

|

| Steel/MgAl pair, dry | 0,10 to 0,25 |

|

|

| Steel/CuZn pair, dry | 0,17 to 0,25 |

|

|

| |

The following table specifies the coefficients of adhesion/coefficients of friction for force fits according to DIN

7190. These values are valid for monotonic loading and are determined for inner parts made of X 210 Cr W12.

They are valid for steel. After joining, the interference fits require sufficient time (24 hours is best) before first

loading to assure a strong joint.

|

|

|

|

|

|

|

| Coefficients of Adhesion for Force Fits During Monotonic Loading

|

|

|

|

|

|

|

|

| Materials | Coefficients of Adhesion

|

|

|

| | | | |

| Old | New | dry | lubricated

|

|

|

| | | | |

| | | Number |  |  |  |  |

|

|

|

|

|

|

|

| St 60-2 | E 335 | 1.0060 | 0,11 | 0,08 | 0,08 | 0,07 |

|

|

|

|

|

|

|

| GS-60 | GE 300 | 1.0558 | 0,11 | 0,08 | 0,08 | 0,07 |

|

|

|

|

|

|

|

| RSt37-2 | S 235JRG2 | 1.0038 | 0,10 | 0,09 | 0,07 | 0,06 |

|

|

|

|

|

|

|

| GG-25 | EN-GJL-250 | 0,6025 | 0,12 | 0,11 | 0,06 | 0,05 |

|

|

|

|

|

|

|

| GGG-60 | EN-GJS-600-3 | 0,7060 | 0,10 | 0,09 | 0,06 | 0,05 |

|

|

|

|

|

|

|

| G-AlSi12 (Cu) | EN AB-44000 ff. | | 0,07 | 0,06 | 0,05 | 0,04 |

|

|

|

|

|

|

|

| G-CuPb10Sn |

CB495K |

2.1176.01 |

0,07 |

0,06 |

- |

- |

| G-CuSn10Pb10 | | | | | | |

|

|

|

|

|

|

|

| TiAl6V4 | TiAl6V4 | 3.7165.10 | - | - | 0,05 | - |

|

|

|

|

|

|

|

| Coefficients of adhesion are unknown

|

|

|

|

|

|

|

|

| |

The above-mentioned table means:

- = Coefficient of adhesion in longitudinal direction for loosening

- = Coefficient of adhesion in longitudinal direction for sliding

The coefficients of adhesive friction/coefficients of friction are dependent upon the following factors:

- Mating of material of inner and outer part,

- Roughness of joining surfaces,

- Condition of joining surfaces before joining (lubricated or not),

- Load of inner and outer part (elastic only or elastic-plastic).

Due to the friction within the joint, the coefficients of adhesive friction are subject to statistical fluctuations.

Therefore, the defined coefficients of adhesive friction are approximate values and are on the safe

side. The values can be replaced by an experimental determination of values according to DIN

7190.

10.9 Stepped Hub Geometry

For the stepped hub or/and shaft (see figure below), there is a larger joint compression on the thick-walled

segment than on the thin-walled segment for the same fit. Hence, widely different stress and deformation ratios

occur on each segment. In that case, the total length  has to be used. The hub can be considered as

composed of separate discs of different diameters. From it, the mean joint pressure for the interference fit is

determined. Because the stresses and deformation cannot change abruptly from one segment to another

segment, this method of segmentation presents an approximation. The effort to define the matching

conditions or to determine the joint compression by using FEM calculation is just useful for critical

cases.

has to be used. The hub can be considered as

composed of separate discs of different diameters. From it, the mean joint pressure for the interference fit is

determined. Because the stresses and deformation cannot change abruptly from one segment to another

segment, this method of segmentation presents an approximation. The effort to define the matching

conditions or to determine the joint compression by using FEM calculation is just useful for critical

cases.

The calculation is determined according to the algorithm in Prof. Hartmanns ‘Berechnung und Auslegung

elastischer Pressverbindungen’.

Click on the button ‘stepped’ next to the input field ‘Outer diameter hub’ to consider the stepped hub geometry.

Any number of segments can be defined.

The figure (see figure 10.15) shows how the segmentation has be specified. A segment can contain a constant

outer hub diameter and inner shaft diameter. If a shaft bore extends over two outer hub diameters of different

size, then two segments has to be defined with a different outer hub diameter and equal inner shaft

diameter. In case there is a stepped shaft bore within a constant hub outer diameter, then use this

method, too (a definition of two segments with equal outer hub diameter and different inner shaft

diameter).

Place a checkmark in order enable and use the stepped hub geometry.

Now you can start to define the segments. Enter the number of segment and add the segment length, outer hub

diameter and inner shaft diameter.

Clicking the ‘OK’ button applies your input values and the diagram button will be enabled.

That diagram shows the compressive stress along the fit length. Move the mouse over the diagram to see the

values for the lowest (pK), highest (pG) and mean (p) compressive stress due to the lowest, highest and mean

interference.

10.10 Subsidence/Surface Smoothing

Due to the smoothness of asperity peaks during the joining, only the interference  is available.

Unless there are experimental values, the equations according to DIN 7190 for force and shrink fits

are:

is available.

Unless there are experimental values, the equations according to DIN 7190 for force and shrink fits

are:

where  is the subsidence that results from the determined surface roughness

is the subsidence that results from the determined surface roughness  of inner and outer part.

of inner and outer part.

is the lowest, highest and mean interference.

is the lowest, highest and mean interference.

If the values of the surface roughness for the arithmetic mean value of the profile coordinates  (formerly

the arithmetical mean deviation of the roughness profile

(formerly

the arithmetical mean deviation of the roughness profile  ) are specified according to DIN EN

ISO 4287, then the determined mean values according to DIN 7190 can be used for the surface

roughness

) are specified according to DIN EN

ISO 4287, then the determined mean values according to DIN 7190 can be used for the surface

roughness  (see table below). Select the entry ‘User defined’ from the listbox ‘Surface’. Now

the input field next to the listbox is enabled and you can enter a value for the surface roughness

(see table below). Select the entry ‘User defined’ from the listbox ‘Surface’. Now

the input field next to the listbox is enabled and you can enter a value for the surface roughness

.

.

10.11 Modification of Diameter

The calculation of the modification of diameter at the inner and outer diameter of shaft and hub takes place

according to Niemanns ‘Maschinenelemente’ volume 1 pp.789, 3rd edition 2001. There, the modification of the

diameter is considered by the joint pressure and centrifugal force. The influence of temperature on the

modification of diameter is considered on the outer diameter of the shaft and on the inner diameter of the hub by

the modified interference and joint pressure.

10.12 Fretting Corrosion

According to Niemann ‘Maschinenelemente’ volume 1 p. 800, 3rd edition 2001, the torque is transmitted also

during repeated load by elastic transformation (i.e., without slip), if the torque  is smaller than the maximum

torque

is smaller than the maximum

torque  . For a solid shaft, disk-shaped hub with

. For a solid shaft, disk-shaped hub with  and shaft and hub with equal E modulus, it

is expressed as:

and shaft and hub with equal E modulus, it

is expressed as:

is the slipping torque against fretting corrosion. This results in remedial measures agaisnt fretting

corrosion. The joint pressure, coefficient of adhesion in terms of circumference, the joint diameter or the

safety against sliding can be increased in order to avoid micro sliding/fretting corrosion. A rotating

bending may cause fretting corrosion. If the mentioned conditions for a possible determination of the

maximum torque are given, the maximum torque is calculated for the minimum, mean and maximum

interference.

is the slipping torque against fretting corrosion. This results in remedial measures agaisnt fretting

corrosion. The joint pressure, coefficient of adhesion in terms of circumference, the joint diameter or the

safety against sliding can be increased in order to avoid micro sliding/fretting corrosion. A rotating

bending may cause fretting corrosion. If the mentioned conditions for a possible determination of the

maximum torque are given, the maximum torque is calculated for the minimum, mean and maximum

interference.

10.13 Assembly and Disassembly

10.13.1 Shrink fits

In shrink fits, the outer member is heated or the inner part is cooled, or both, as required. The calculation of the

temperatures to cool the inner part or to heat the outer part is dependent upon the chosen minimum fit.

Additionally, a mating clearance for joining has to be kept to avoid adhesion. For an individual production, it is

recommended to use the following mating clearance

For the individual production the risk of premature adhesion of the joining parts is covered before the assembly

process is completed. By using joining devices, the above recommended mating clearance can be fallen below.

Click on the button ‘Options’ to define the mating clearance. Two possibilities are available. On the one hand, the

mating clearance can be specified dependent upon the joint diameter, on the other hand a mating clearance can

be entered directly in  .

.

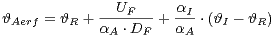

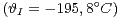

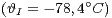

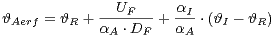

In general, the room temperature as well the joint temperature of the inner part are set. The required joint

temperature is calculated as follows:

The button ‘Options’ allows to change the room temperature and the joint temperature of the shaft (see section

10.23 ‘The Button Options’). The highest joint temperature may not exceed the required work piece features of

the heat-treated parts.

In the following table, the data according DIN 7190 valid data are specified for the maximum joint temperatures

dependent on the material of the outer part and the heat treatment.

|

|

| Joint Temperature

|

|

|

| Material of the Outer Part (Hub) | Joint Temperature  C Maximum C Maximum |

|

|

| Structural steel lower strength | |

| Cast steel | 350 |

| Modular cast iron | |

|

|

| Hardened and tempered steel or cast steel | 300 |

|

|

| Surface layer hardened steel | 250 |

|

|

| Case-hardened steel or high-tempered structural steel | 200 |

|

|

| |

The following table provides the coefficients of linear thermal expansion for inner and outer part.

|

|

|

|

|

|

|

| Poissons Ratio, Elastic Modulus, Coefficient of Linear Thermal Expansion

|

|

|

|

|

|

|

|

| Materials | Material | Poissons | Elastic Modulus | Coefficient of Linear

|

| | No. | Ratio |

| Thermal Expansion  |

| | |  |  |

|

| | |  | | Heating  Supercool |

|

|

|

|

|

|

|

| MgAl8Zn | 3.5812 | 0,3 | | | |

| AlMgSi | 3.2315 | 0,34 | 65 000 to 75 000 | 23 | -18 |

| AlCuMg | 3.1325 | 0,33 to 0,34 | | | |

|

|

|

|

|

|

|

| GG-10 | 0.6010 | | 70 000 | | |

| GG-15 | 0.6015 | 0,24 | 80 000 | 10 | -8 |

|

|

|

| | | |

| GG-20 | 0.6020 | | 105 000 | | |

| GG-25 | 0.6025 | 0,24 to 0,26 | 130 000 | | |

|

|

|

|

|

|

|

| GGG-50 | 0.7050 | 0,28 to 0,29 | 140 000 | 10 | -10 |

|

|

|

|

|

|

|

| Malleable cast iron | | 0.25 |  90 000 to 100 000 90 000 to 100 000 | 10 | -8 |

|

|

|

|

|

|

|

| C-steel low alloyed | | 0,3 to 0,31 | | | |

| Ni-steel | | 0,31 | 200 000 to 235 000 | 11 | -8,5 |

|

|

|

|

|

|

|

| Bronze | | 0,35 | | 16 | -14 |

|

|

| |

|

| |

| Red brass | | 0,35 to 0,36 | 80 000 to 85 0000 | 17 | -15 |

|

|

| |

|

| |

| CuZn39Pb3 | 2.0401 | 0,37 | | | |

| CuZn37 | 2.0321 | 0,36 | | 18 | -16 |

|

|

|

|

|

|

|

| Not allowed for system engineering in metallurgy/rolling mills

|

|

|

|

|

|

|

|

| |

Liquid nitrogen  is used to cool shrink fits. Liquid nitrogen shrink fitting is one of the safest

assembly methods. In some cases

is used to cool shrink fits. Liquid nitrogen shrink fitting is one of the safest

assembly methods. In some cases  dry ice

dry ice  is also used as a coolant. Based on the

maximally permissable temperature of the hub, it must be decided whether the cooling process is necessary or

not.

is also used as a coolant. Based on the

maximally permissable temperature of the hub, it must be decided whether the cooling process is necessary or

not.

10.13.2 Force Fits

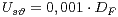

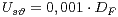

The required pressing force for joining is determined from:

The ‘Option’ button allows to define the coefficients of adhesion  for pressing in and pressing out (see also

section 10.23 ‘The Button Options’). The table (see table 10.8) specifies the coefficient of adhesion

for pressing in and pressing out (see also

section 10.23 ‘The Button Options’). The table (see table 10.8) specifies the coefficient of adhesion  . The

maximum joint pressure

. The

maximum joint pressure  is determined for the highest interference. In case the joining surfaces

are not lubricated with grease, larger coefficients of friction and larger longitudinal and tangential

forces occur. There is a risk of scuffing for joining surfaces that are not lubricated, in particular

for a elastic-plastic dimensioning. Before joining, the joining surfaces should be lubricated with

oil.

is determined for the highest interference. In case the joining surfaces

are not lubricated with grease, larger coefficients of friction and larger longitudinal and tangential

forces occur. There is a risk of scuffing for joining surfaces that are not lubricated, in particular

for a elastic-plastic dimensioning. Before joining, the joining surfaces should be lubricated with

oil.

Furthermore, the following information has to be considered for the engineering design according to DIN

7190:

The values for the edge length  are specified in the following table. The measurement is indicated in

mm.

are specified in the following table. The measurement is indicated in

mm.

During the manufacturing process of interference fits by force fitting, the joining area is provided with a thin oil

film over the entire surface. A jamming of the assembled parts must be avoided. The slip-stick effect can be

avoided by the press-in speed and discharge speed of approx. 50 mm/s and sufficient pressing force (2,5x

extraction force). Force fits requires sufficient time (24 hours) before first loading, then the complete adhesive

force is reached (only 70% immediately after pressing).

10.14 Example of Interference Fits

The following section gives some guidance on selecting fits according to E. & K. Felber. There are features

that can be expected in general during the assembly. The assembly rules specify the character of

the fit and all features correspond to the mean value of fits. The list contains fits that are used

frequently. Almost all fits can be formed in quality (e.g., from H8/u8 to H8/u7 to H6/u6). In general, the

standard fits (e.g., H8/u7) can be used. According to the function, you have to select fine qualities

(e.g., H6/u6) for larger requirements (requirements for accuracy and uniformity). The following

examples are taken from the mechanical engineering and cannot to be considered as complete in any

detail.

Examples for interference fits: H8/u8; U8/h7; H8/s7; S7/h6; H7/r6; R7/h6

Features, assembly rule: The parts are assembled and tightened and have a strong interference. The parts

are pressed together or assembled into position while hot and cooled. In general, a safety device against torsion

or shifting in lengthwise direction is not necessary.

Examples: Spur gears that are mounted tightly on a shaft, couplings, collar rings, press rings, wheel rims,

bearing bushings in housings, bushings in gear hubs, tight pivots, bushings made of synthetic resin pressed

material, parts which cannot be loosened by large forces.

10.15 How to Change the Unit of Measurement

Use this function if you want to change the unit of measurement quickly. Just a right-click on the input field

where you want to change the unit. The context menu contains all available units. The two arrows mark the

current setting. As soon as you select a unit, the current field value will be converted automatically into the

chosen unit of measurement.

10.16 The Button ‘Redo’ and ‘Undo’

The button ‘Undo’ allows you to reset your input to an older state. The button ‘Redo’ reverses the

undo.

10.17 Material Selection

Clicking the button ‘Material’ opens the material database. In case there is no material that will fulfill the design

requirements, then simply define your individual material. You will find the entry ‘User-defined’ in

the listbox. If you select this option, the input fields will be enabled, so that you can enter your

own input values or add a comment. Please select the material from the list. You will get detailed

information on the material. The two cursor keys ‘Up’ and ‘Down’ of your keyboard allows you to navigate

through the material database, so you can compare the different material properties with each

other.

10.18 Message Window

The calculation module provides a message window. This message window displays detailed information,

helpful hints or warnings about problems. One of the main benefits of the program is that the software provides

suggestions for correcting errors during the data input. If you check the message window carefully for any

errors or warnings and follow the hints, you are able to find a solution to quickly resolve calculation

problems.

10.19 Quick Info: Tooltip

The quick info feature gives you additional information about all input fields and buttons. Move the mouse pointer

to an input field or a button, then you will get some additional information. This information will be displayed in

the quick info line.

10.20 Calculation Results

All important calculation results, such as the lowest, highest and mean interference, will be calculated during

every input and will be displayed in the result panel. A recalculation occurs after every data input. Any changes

that are made to the user interface take effect immediately. Press the Enter key or move to the

next input field to complete the input. Alternatively, use the Tab key to jump from field to field or

click the ‘Calculate’ button after every input. Your entries will be also confirmed and the calculation

results will displayed automatically. If the result exceeds certain values, the result will be marked

red.

10.21 Documentation: Calculation Report

After the completion of your calculation, you can create a calculation report. Click on the ‘Report’

button.

You can navigate through the report via the table of contents that provides links to the input values, results and

figures. This calculation report contains all input data, the calculation method as well as all detailed results. The

report is available in HTML and PDF format. The calculation report saved in HTML format, can

be opened in a web browser or in Word for Windows. You may also print or save the calculation

report:

- To save the report in the HTML format, please select ‘File’

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

- If you click on the symbol ‘Print’, then you can print the report very easily.

- When you click on the symbol ‘PDF’, then the report appears in the PDF format. If you right-click

on the PDF symbol, you should see the ‘Save Target As’ option. Click on that option and you will

see the dialog box for saving the report.

10.22 How to Save the Calculation

When the calculation is finished, you can save it to your computer or to the eAssistant server. Click on the button

‘Save’.

Before you can save the calculation to your computer, you need to activate the checkbox ‘Enable

save data local’ in the project manager and the option ‘Local’ in the calculation module. A standard

Windows dialog for saving files will appear. Now you will be able to save the calculation to your

computer.

In case you do not activate the option in order to save your files locally, then a new window is opened and you

can save the calculation to the eAssistant server. Please enter a name into the input field ‘Filename’ and click on

the button ‘Save’. Then click on the button ‘Refresh’ in the project manager. Your saved calculation file is

displayed in the window ‘Files’.

10.23 The Button ‘Options’

Click the button ‘Options’ in order to change the default settings. The button ‘Options’ allows you to define the

minimum safeties, the mating clearance, the temperatures at joining (room temperature and shaft temperature)

as well as the coefficient of friction at joining for pressing in and pressing out for a force fit. Additionally, there is

the possibility to enter the number of decimal places for the output of the numerical values in the

report.

Here are the default settings that you can modify:

- Minimum safeties

- Mating clearance

- Temperatures at joining

- Coefficient of friction at joining

10.24 Calculation Example: Interference Fit According to DIN 7190

10.24.1 Start the Calculation Module

Please login with your username and your password. Select the module ‘Interference fit’ through the tree

structure of the project manager by double-clicking on the module or clicking on the button ‘New

calculation’.

10.24.2 Calculation Example

A cylindrical interference fit has to be dimensioned against sliding. Enter the following values:

| Outer diameter hub | | | | | = 95 mm |

| Inner diameter shaft | | | | | = 30 mm |

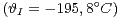

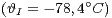

| Operating temperature | | | | | =  C C |

| Coefficient of friction axial | | | | | = 0.15 |

| Coefficient of friction circumference | | | | | = 0.15 |

| Material hub | | | | | = C45 hardened and tempered |

10.24.3 Start the Calculation

Please start to enter the values into the input field. All important calculation results will be calculated during

every input and will be displayed in the result panel. A recalculation occurs after every data input. During the

input of the values it can happen that the results will be marked in red. Nevertheless, please continue to input

the data as usual.

Please note: Please note the section ‘Selection of fit’ for the specification of the tolerances. With the definition

of the surface quality of the hub, you have to notice that the given value (Rz=6) has to be entered by the ‘User

defined’ input. Select ‘User defined’ in the appropriate listbox and enter the desired value into the input field next

to the listbox.

Selection of Fit / Calculation of Possible Fits

The button ‘Selection’ allows you to open the dialog window for selection of fits. Here you can choose the

possible tolerances or the appropriate fits can be suggested.

Enable ‘Show only preferred fits’ and click the button ‘Search fits’.

Two fits will be recommended to you.

Select the fit H7/s6 and click the button ‘Ok’.

Automatic Dimensioning of the Maximum Torque

Due to the fit calculation, a safety close to the given minimum safety has been determined. By the help of the

comfortable dimensioning functions, other values can be checked and optimized regarding the use of the

minimum safety. So the maximum torque can be defined using the given minimum safety against sliding

. The button ‘Options’ allows you to specify the minimum safety. Click on the dimensioning button

(‘calculator symbol’) next to the input field for the torque.

. The button ‘Options’ allows you to specify the minimum safety. Click on the dimensioning button

(‘calculator symbol’) next to the input field for the torque.

The maximum torque is determined.

Here the maximum torque is ‘83.60 Nm’. If you enter now a higher value than ‘83.60 Nm’, the safety against

sliding is fallen below.

The calculation result is marked in red. You will get an appropriate information in the message

window.

Now click on the calculator symbol again, then the maximum torque is determined (83.50 Nm)

and the minimum safety of ‘1.2’ is fulfilled. The specifications of the results is given for the lowest,

highest and mean interference. If the minimum safety is not fulfilled, then the safety is marked in

red.

10.24.4 Calculation Results

All important calculation results, such as the lowest, highest and mean interference, will be calculated during

every input and will be displayed in the result panel. A recalculation occurs after every data input. Any changes

that are made to the user interface take effect immediately. If the result exceeds certain values (e.g., the

minimum saftey), the result will be marked red.

10.24.5 Documentation: Calculation report

In case you have finished your calculation, please click on the button ‘Report’.

The calculation report contains a table of contents. You can navigate through the report via the table of contents

that provides links to the input values, results and figures. The report is available in HTML and PDF

format. Calculation reports, saved in HTML format, can be opened in a web browser or in Word for

Windows.

You may also print or save the calculation report:

- To save the report in the HTML format, please select ‘File’

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

- If you click on the symbol ‘Print’, then you can print the report very easily.

- If you click on the symbol ‘PDF’, then the report appears in the PDF format. If you right-click on the

PDF symbol, you should see the ‘Save Target As’ option. Click on that option and you will see the

dialog box for saving the report.

10.24.6 How to Save the Calculation

When the calculation is finished, you can save it to your computer or to the eAssistant server. Click on the button

‘Save’.

Before you can save the calculation to your computer, you need to activate the checkbox ‘Enable

save data local’ in the project manager and the option ‘Local’ in the calculation module. A standard

Windows dialog for saving files will appear. Now you will be able to save the calculation to your

computer.

In case you do not activate the option in order to save your files locally, then a new window is opened and you

can save the calculation to the eAssistant server. Please enter a name into the input field ‘Filename’ and click on

the button ‘Save’. Then click on the button ‘Refresh’ in the project manager. Your saved calculation file is

displayed in the window ‘Files’.

Our manual is improved continually. Of course we are always interested in your opinion,

so we would like to know what you think. We appreciate your feedback and we are

looking for ideas, suggestions or criticism. If you have anything to say or if you

have any questions, please let us know by phone +49 (0) 531 129 399-0 or email

eAssistant@gwj.de.

that is

necessary for the power transmission, is generated by the deformation of shaft and hub. According to the

manufacturing method, you have to distinguish between a shrink and force fit. Shrink-fitting is a procedure in

which heat is used to produce a very strong joint between two pieces of metal, one of which is

inserted into the other. Heating causes one piece of metal to contract or expand on to the other,

producing interference and pressure which holds the two pieces together. In a force fit of cylindrical

parts, the inner member has a greater diameter than the hole of the outer member. The calculation

takes place according to DIN 7190 for cylindrical interference fits. In addition, the influence of the

centrifugal force, the stepped hub geometry, torque, radial force and bending moment are considered as

well.

that is

necessary for the power transmission, is generated by the deformation of shaft and hub. According to the

manufacturing method, you have to distinguish between a shrink and force fit. Shrink-fitting is a procedure in

which heat is used to produce a very strong joint between two pieces of metal, one of which is

inserted into the other. Heating causes one piece of metal to contract or expand on to the other,

producing interference and pressure which holds the two pieces together. In a force fit of cylindrical

parts, the inner member has a greater diameter than the hole of the outer member. The calculation

takes place according to DIN 7190 for cylindrical interference fits. In addition, the influence of the

centrifugal force, the stepped hub geometry, torque, radial force and bending moment are considered as

well.

C in an electric kiln

C in an electric kiln  C in an electric kiln

C in an electric kiln

has to be used. The hub can be considered as

composed of separate discs of different diameters. From it, the mean joint pressure for the interference fit is

determined. Because the stresses and deformation cannot change abruptly from one segment to another

segment, this method of segmentation presents an approximation. The effort to define the matching

conditions or to determine the joint compression by using FEM calculation is just useful for critical

cases.

has to be used. The hub can be considered as

composed of separate discs of different diameters. From it, the mean joint pressure for the interference fit is

determined. Because the stresses and deformation cannot change abruptly from one segment to another

segment, this method of segmentation presents an approximation. The effort to define the matching

conditions or to determine the joint compression by using FEM calculation is just useful for critical

cases.

is available.

Unless there are experimental values, the equations according to DIN 7190 for force and shrink fits

are:

is available.

Unless there are experimental values, the equations according to DIN 7190 for force and shrink fits

are:

is the subsidence that results from the determined surface roughness

is the subsidence that results from the determined surface roughness  of inner and outer part.

of inner and outer part.

is the lowest, highest and mean interference.

is the lowest, highest and mean interference.

(formerly

the arithmetical mean deviation of the roughness profile

(formerly

the arithmetical mean deviation of the roughness profile  ) are specified according to DIN EN

ISO 4287, then the determined mean values according to DIN 7190 can be used for the surface

roughness

) are specified according to DIN EN

ISO 4287, then the determined mean values according to DIN 7190 can be used for the surface

roughness  (see table below). Select the entry ‘User defined’ from the listbox ‘Surface’. Now

the input field next to the listbox is enabled and you can enter a value for the surface roughness

(see table below). Select the entry ‘User defined’ from the listbox ‘Surface’. Now

the input field next to the listbox is enabled and you can enter a value for the surface roughness

.

.

in

in

in

in

in

in

is smaller than the maximum

torque

is smaller than the maximum

torque  . For a solid shaft, disk-shaped hub with

. For a solid shaft, disk-shaped hub with  and shaft and hub with equal E modulus, it

is expressed as:

and shaft and hub with equal E modulus, it

is expressed as:

is the slipping torque against fretting corrosion. This results in remedial measures agaisnt fretting

corrosion. The joint pressure, coefficient of adhesion in terms of circumference, the joint diameter or the

safety against sliding can be increased in order to avoid micro sliding/fretting corrosion. A rotating

bending may cause fretting corrosion. If the mentioned conditions for a possible determination of the

maximum torque are given, the maximum torque is calculated for the minimum, mean and maximum

interference.

is the slipping torque against fretting corrosion. This results in remedial measures agaisnt fretting

corrosion. The joint pressure, coefficient of adhesion in terms of circumference, the joint diameter or the

safety against sliding can be increased in order to avoid micro sliding/fretting corrosion. A rotating

bending may cause fretting corrosion. If the mentioned conditions for a possible determination of the

maximum torque are given, the maximum torque is calculated for the minimum, mean and maximum

interference.

.

.

Supercool

Supercool 90 000 to 100 000

90 000 to 100 000  is used to cool shrink fits. Liquid nitrogen shrink fitting is one of the safest

assembly methods. In some cases

is used to cool shrink fits. Liquid nitrogen shrink fitting is one of the safest

assembly methods. In some cases  dry ice

dry ice  is also used as a coolant. Based on the

maximally permissable temperature of the hub, it must be decided whether the cooling process is necessary or

not.

is also used as a coolant. Based on the

maximally permissable temperature of the hub, it must be decided whether the cooling process is necessary or

not.

for pressing in and pressing out (see also

section

for pressing in and pressing out (see also

section  . The

maximum joint pressure

. The

maximum joint pressure  is determined for the highest interference. In case the joining surfaces

are not lubricated with grease, larger coefficients of friction and larger longitudinal and tangential

forces occur. There is a risk of scuffing for joining surfaces that are not lubricated, in particular

for a elastic-plastic dimensioning. Before joining, the joining surfaces should be lubricated with

oil.

is determined for the highest interference. In case the joining surfaces

are not lubricated with grease, larger coefficients of friction and larger longitudinal and tangential

forces occur. There is a risk of scuffing for joining surfaces that are not lubricated, in particular

for a elastic-plastic dimensioning. Before joining, the joining surfaces should be lubricated with

oil.

are specified in the following table. The measurement is indicated in

mm.

are specified in the following table. The measurement is indicated in

mm.

should not exceed

should not exceed  .

.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

C

C

. The button ‘Options’ allows you to specify the minimum safety. Click on the dimensioning button

(‘calculator symbol’) next to the input field for the torque.

. The button ‘Options’ allows you to specify the minimum safety. Click on the dimensioning button

(‘calculator symbol’) next to the input field for the torque.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.

‘Save as’ from your browser menu

bar. Select the file type ‘Webpage complete’, then just click on the button ‘Save’.